By continuing to browse the site you are agreeing to our use of cookies. For more details about cookies and how to manage them, see our cookie policy.

Aktogay is a large scale, low cost open pit mine with a remaining mine life of around 25 years. The annual sulphide processing design capacity was doubled to 50 million tonnes following the commissioning of the second sulphide concentrator in October 2021, which ramped up during 2022.

Aktogay has a remaining mine life of around 25 years (including the expansion project) at an average copper grade of 0.27% (oxide) and 0.34% (sulphide).

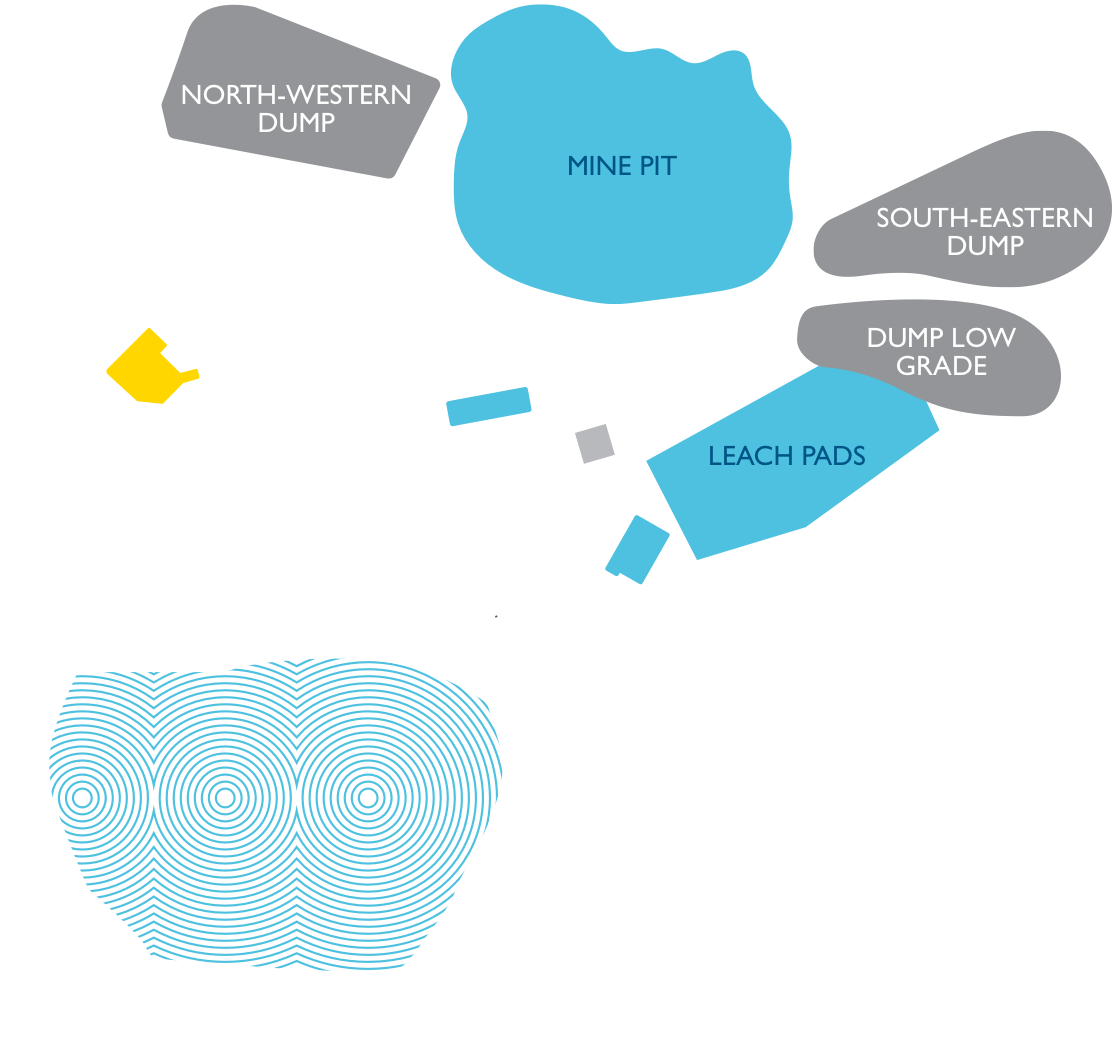

The Aktogay site has an annual sulphide ore processing capacity of 50 million tonnes from two concentrators. Aktogay is competitively positioned on the global cost curve and is expected to produce an average of 170 kt of copper per year from 2022 to 2027.

Unlike Bozshakol, which was a green field site when we started working there, Aktogay had the advantage of some existing infrastructure including power and transportation links. We carried out surveying works on the intended location of the concentrator and started removing top soil to prepare the area for the camps and main buildings.

We made further progress with the earthworks for the main buildings, continued removing top soil and improving the roads. We established the temporary camp and offices and started preparing the ground for the permanent camp. We started work on the construction of the main drainage trench for the heap leach pad and began to pour the concrete foundations of the main processing plants. In Q4, we finished off infrastructure links including rail tracks and the 110 kV transmission lines.

The contract for the construction of the sulphide concentrator was awarded to Non Ferrous China (“NFC”) in September 2014, the largest item in the capital expenditure budget for Aktogay. Following this contract award the Group was able to confirm that the total capital cost for the Aktogay project was expected to be in the region of $2.3bn (later reduced to $2.0bn). In the first half of 2014 we completed 50% of the construction of 110 kV overhead transmission line and commenced bulk earthworks at the site. The assembly of mining equipment continued. The contractor for the heap leach plant mobilised and commenced foundation works. We started the construction and installation of the water pipeline and railway spurs.

In the first half of 2015 we completed the acid storage facilities and the PLS pump house, sulphide plant foundations and the first two oxide heap leach cells (101 and 102) were completed and ready to receive ore. The construction of the oxide plant buildings and processing facilities, heap leach cells 103-109 and the permanent camp were completed in time for the commencement of cathode production from oxide ore in December 2015. At the sulphide project, the sites for the primary crusher and conveyor were prepared.

Works on the main sulphide concentrator were substantially completed in 2016 and commissioning works began in December, with production of saleable copper concentrate following in February 2017. The capital budget for the project has been reduced by over $270 million to approximately $2.0 billion.

In December 2017 the Board approved a $1.2 billion expansion project to double sulphide ore processing capacity from 25 million tonnes to 50 million tonnes, with first production expected in the second half of 2021.

During 2018 initial excavation and earthworks were completed and long lead-time equipment orders were placed. Our recent experience in building facilities of this type will enable us to execute a greater proportion of the project using the Group’s in-house management capabilities than we did with Bozshakol and Aktogay, working closely with proven local and international contractors and suppliers.

In H1 2019 the Group has continued to make good progress with the expansion project at Aktogay. Foundations for grinding and flotation equipment were successfully laid and the erection of structural steel is largely complete. The Group has taken delivery of and put into operation the first of the new larger mining fleet vehicles, including Caterpillar 793 mine haul tracks and 994 loaders, which will deliver the increased ore extraction volumes required for the second concentrator.

Construction works at the Aktogay expansion project were affected by reduced staff availability in the first half of 2020, however works progressed according to plan in the second half of the year as Covid-19 related restrictions were eased and the Group’s testing and isolation measures enabled shift changes to take place safely. Construction of the crusher, conveyor, ore reclaim, mills and flotation sections of the concentrator is complete and the focus is now on equipment installations, electrical and pipeline connections and testing. The new electrical supply for the second concentrator has been completed and energised. Construction work is continuing on the tailings thickeners and pump house, pebble crusher, HPGR and bagging plant. The new camp facilities are 75% complete. Initial production from the Aktogay expansion is on track to commence by the end of 2021, as previously guided.

In October 2021 the Aktogay expansion project was opened by the President of the Republic of Kazakhstan. The second concentrator doubles the sulphide ore processing capacity at the site to 50 Mtpa. Despite the challenges presented by the Covid-19 pandemic, the Aktogay expansion project was built on schedule and on budget, continuing the Group's successful track record of project delivery.

The second sulphide concentrator at Aktogay achieves ore throughput design capacity, a significant milestone in the project’s world-class ramp-up.